Single-channel pressure spray pump head and dual-channel spray pump head

1. The working principle of single-channel and dual-cha […]

1. The working principle of single-channel and dual-channel pressure of spray pump head

The single-channel pressure spray pump head is also called a simple centrifugal nozzle. As the name suggests, it uses swirling parts in the nozzle to generate liquid rotation and accelerates spraying of FFJ core diffusion cone-shaped oil film in the convergent channel, using the high speed difference between the liquid and the outside air. And broken and atomized. Among them, the centrifugal force of the swirling flow is used, so the cyclone is a key component. The swirl chamber and nozzle connected to the swirler (sheet) are equally important. They can be integrated (collectively referred to as atomizers), or separated into single-piece combinations.

There are two oil circuits (main and auxiliary oil circuits or primary and secondary oil circuits) in the dual oil pressure spray pump head for oil supply. When the fuel supply in the combustion chamber is small, that is, under low operating conditions (such as engine slow-bull state), only the auxiliary oil circuit (one way) supplies fuel. As the fuel supply increases, the fuel pressure rises to a certain value. The oil divider valve (spring-type valve) inside or outside the nozzle is opened, and the main and auxiliary oil circuits supply oil at the same time. Dual-channel is an improved type of single-channel pressure spray pump head. Its outstanding advantage is that it has a large oil volume adjustment range and can ensure low operating conditions (low fuel supply). Due to the small diameter of the auxiliary oil channel nozzle, the oil pressure can still be Higher, better atomization quality can be obtained (especially prominent for dual-channel dual-chamber dual-nozzle nozzles, for dual-channel single-jet door nozzles, it can be obtained by reliably increasing the swirl velocity), which can meet different working conditions of aviation gas turbines at high and low altitudes Requirements for stable combustion and complete combustion. Therefore, two-way nozzles are widely used in aviation gas turbines, and are also widely used in ground gas turbines.

2.The structural characteristics of the single-channel and dual-channel pressure of the spray pump head

The single-channel pressure spray pump head has simple structure and good atomization quality. It is widely used in various types of combustion devices. Although the oil volume adjustment ratio range is small, it has been widely used in aircraft afterburners. Currently in the main combustion chamber The above is still used as the starting nozzle and the working nozzle, and the combined atomization device of the high-performance aviation gas turbine is used as the core nozzle. In addition, in non-combustion equipment, such as spray drying equipment, the pressure atomization method also uses a single-channel pressure spray pump head. Burners (or burners) on industrial furnaces and boilers also use it.

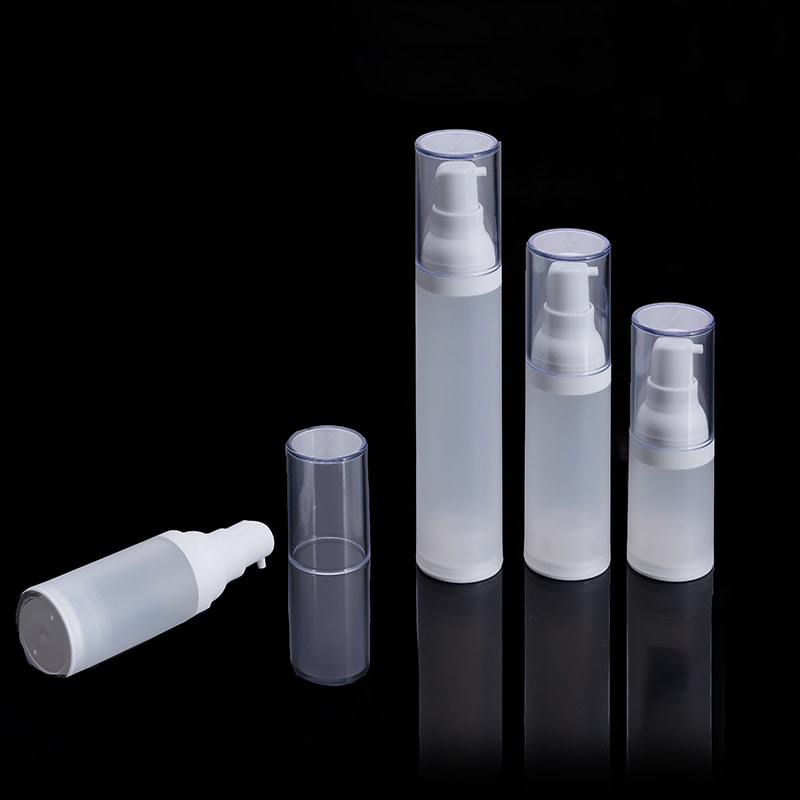

There are many structural forms of the dual-channel pressure spray pump head. Here we introduce the spray pump heads with three structures: dual-channel single-chamber single nozzle nozzle, dual-channel dual-chamber single nozzle nozzle, and dual-channel dual-chamber dual nozzle nozzle.

In order to accurately design and calculate the single-channel pressure spray pump head and the dual-channel spray pump head, the current design method is based on the maximum flow principle method and the momentum equation method. In addition, we have developed or improved many design methods on this basis.