What are the physical and mechanical indicators of cosmetic packaging materials

The mechanical properties of cosmetic packaging play a […]

The mechanical properties of cosmetic packaging play a very important role in the packaging process, transportation, and shelf life of cosmetics. The quality of the food directly determines the safety of the food in the circulation link. Summary of all test items including: tensile strength and elongation, composite film peel strength, heat seal strength, sealing and leakage, impact resistance, material surface slip performance and other indicators

Testing the thickness of cosmetic packaging materials

Whether the thickness of cosmetic packaging materials (film or sheet) is uniform or not is the basis for testing various properties of the film. The uneven thickness of the film will not only affect the tensile strength and barrier properties of the film, but also affect the subsequent processing of the film. There are many methods for measuring thickness, generally divided into non-contact and contact: non-contact includes radiation, eddy current, ultrasonic, etc.; contact industry is also called mechanical thickness measurement, divided into point contact and surface Contact. At present, the laboratory testing of cosmetic film thickness adopts the mechanical surface contact test method, which is also used as the arbitration method of thickness.

Cosmetic packaging sealing and leak detection

The sealing and leakage detection of cosmetic packaging refers to the characteristics of the packaging bag to prevent other substances from entering or the contents from escaping. There are two commonly used detection methods, the underwater decompression method and the positive pressure detection method.

Headspace analysis of cosmetic packaging

Oxygen and water vapor are the main factors that affect the shelf life of most products. Studies have found that controlling the proportion of gas components in cosmetic packaging can effectively extend the shelf life of the product or improve the quality of storage. A small amount of air remains in the packaging when cosmetics are filled. , If you want to detect and analyze the oxygen or headspace gas analysis in the packaging bag, you need to use a headspace gas analyzer.

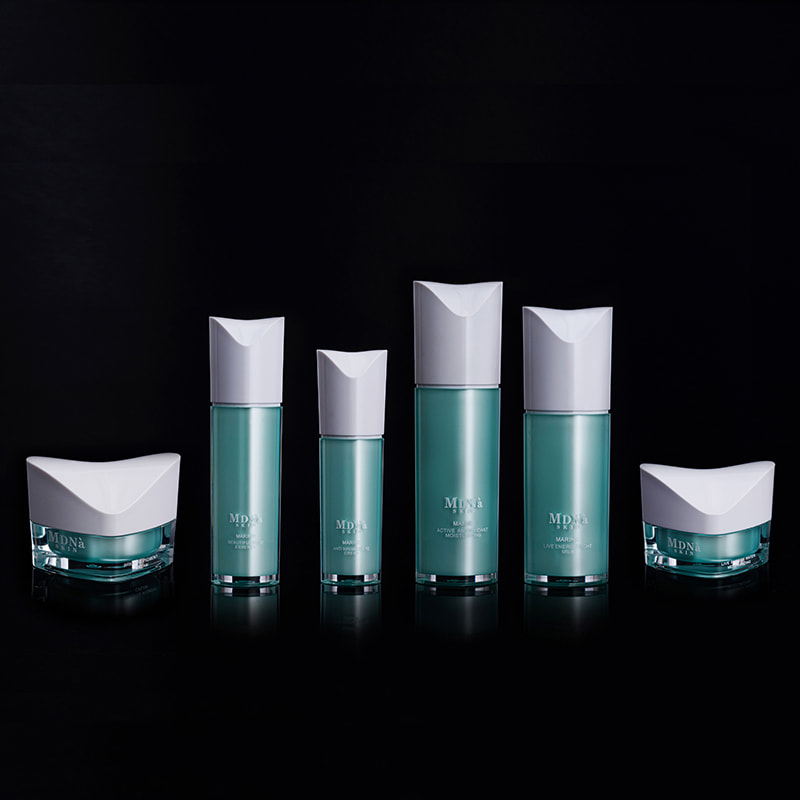

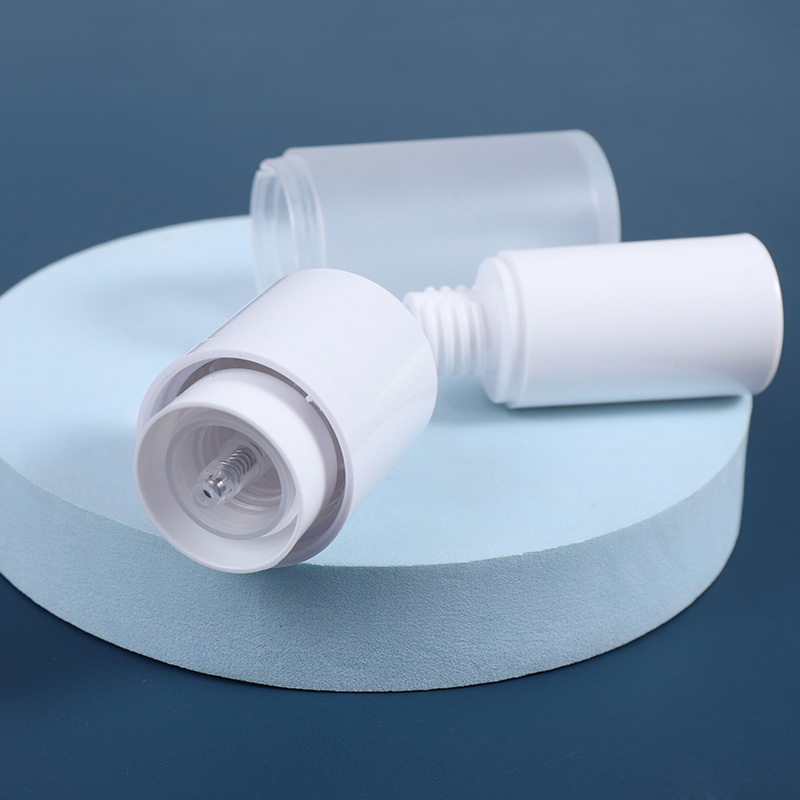

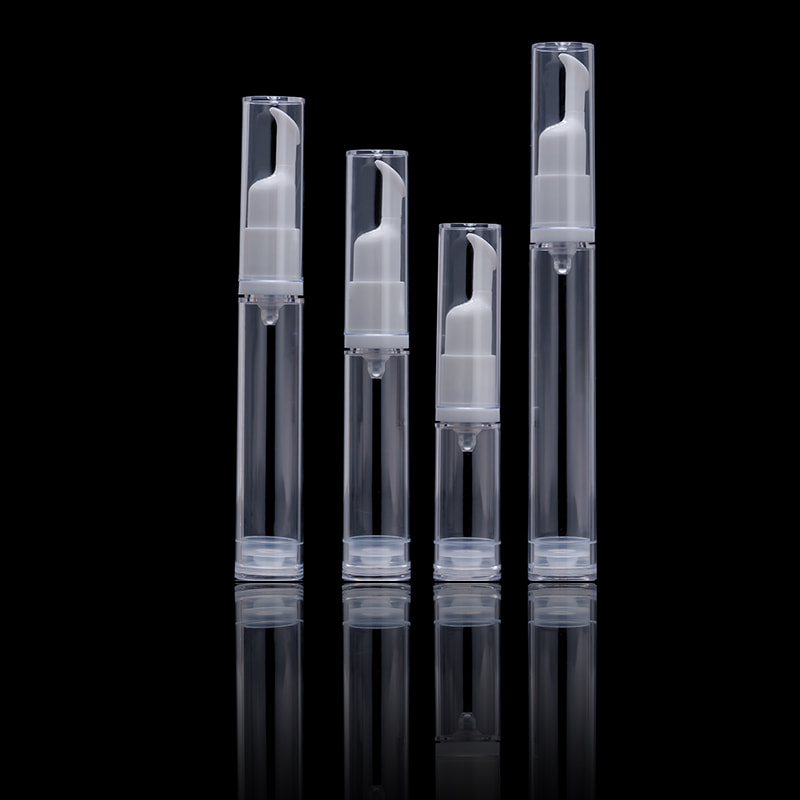

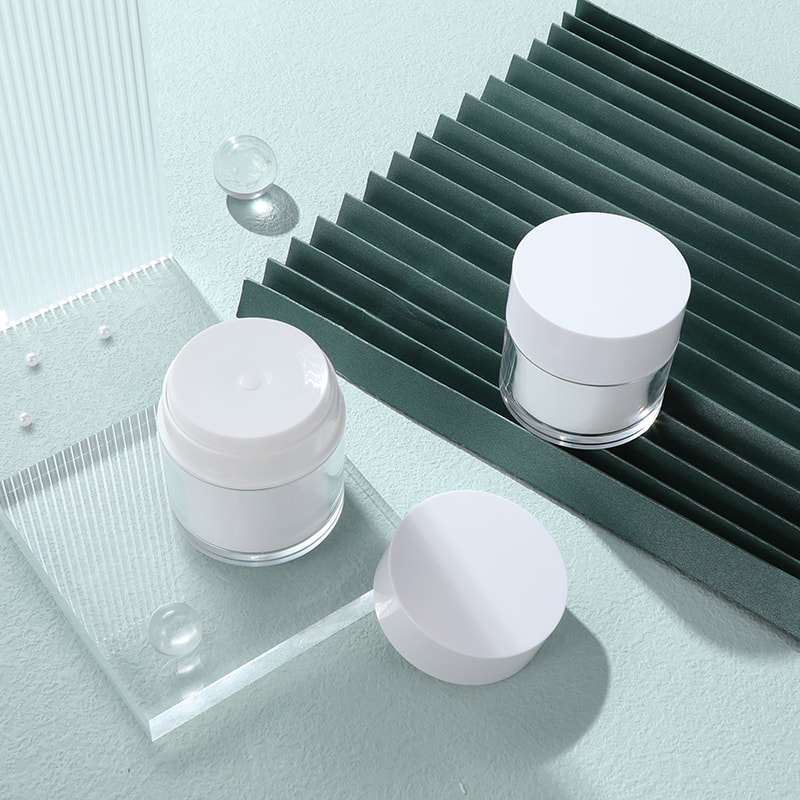

Cosmetic bottle packaging testing instrument

Bottle packaging is the most commonly used form of packaging in the packaging field now. The value of the cap locking and opening torque is one of the key process parameters controlled by the production unit offline or online. Whether the torque value is appropriate has a great influence on the intermediate transportation of the product and the final consumption. The opening and locking force of the bottle cap needs to be tested with the NLY-20 torque meter.